Universal Robots collaborative robot solutions from Tech-Con

The manufacturing companies turn to automatization worldwide, to solve their problems connected to a shortage of labort increase their manufacturing capacity and improve the quality of their products. Collaborative robots offer a cost efficient, flexible and safe automation solution for a wide range of manufacturing tasks.

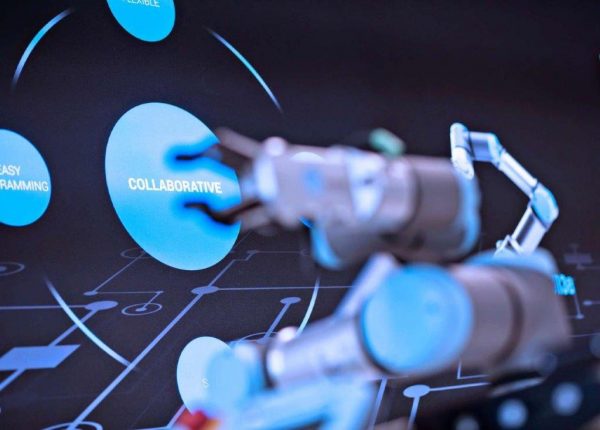

WHY TO CHOOSE COBOTS

Collaborative robots were designed to work in the same place with humans, so the automatization becomes easier than ever, unrelated to the size of the company. Thanks to all these advantages, our robots can take huge variety of task to the next level.

Fast setup

Universal Robots revolutionized the process of the installation of robots, which in this way instead of weeks can be measure in hours. According to the responses of our customers, the avarage time of installation is just half a day. Observations show that it only takes one hour to unbox, install and program the first easy task on the robot, for an employee without vocational training.

Easy programming

Universal Robots patented technology makes it possible that employees with no programming knowledge can install and operate our cobots. Thanks to the intuitive 3D visualisation, it is only needed to lead the robot through the wanted motion manually, but the motion can be given with the easy-to-use, touchscreen tablet’s arrow buttons.

Flexible automation

Do not limit yourself with traditional robots, that can only do one thing. Our robots are lightweight, take up small places and can easily be assigned with new and new tasks. All without moving the manufacturing area. The cobot switches to new processes easily and rapidly, hence manufacturing procedures with rapid changes or happening in small quantities can be automatized easily.

Book now a free on-site survey and robot demo from our expert!

COBOTS IN THE INDUSTRY

Universal Robots cooperating robotic arms increase the performance in countless parts of the industry and create added value. Take a look at how the collaborative robot’s industry can help in automatization. Universal Robots cobots make flexible automatization possible, no matter how big the manufacturer is. Whether we are talking about assembling, painting, palletizing, bolting, packaging, polishing, injection moulding, welding or any other processing procedure, our family of robotic arms can increase the rate of production, with which you can compete in the global market.

Automotive

Food & Agriculture

Metal and Machining

Pharma and Chemistry

Pick and Place

Scientific and Research

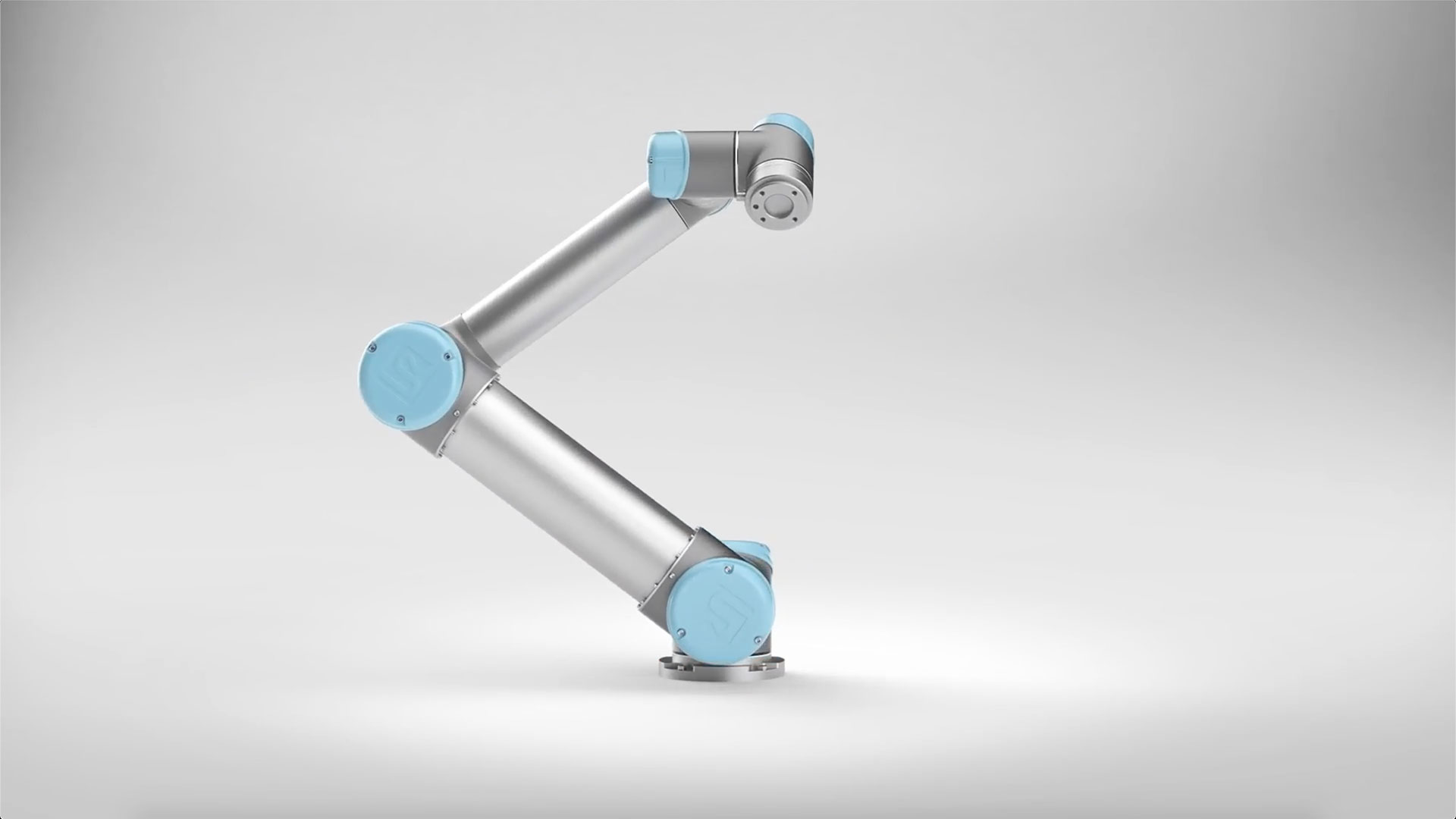

COLLABORATIVE ROBOTS BY UNIVERSAL ROBOTS

Our family of cobots offer four different load-bearing capacity options (3, 5, 10 and 16 kgs), with which it can supply a wide variety of applications. Our cobots with six levels of independence, unbelievable flexibility and easy integration into present manufacturing environments were created so they can offer more.

Choose the collaborative robot arm that fits your needs the most!

ROBOTS

Leasing option

Tech-Con in partnership with GRENKE has launched a new leasing and financial services program.. The new partnership, regardless of size and budget, will allow all businesses to enjoy the benefits of automation without having to worry about cash flow or seasonal fluctuations.

Contact our expert for more information

Additional products

In addition to the collaborative robot offer of Universal Robots, our company, with its professional support, product portfolio and logistics background, is unique in the Romarian market and provides its partners with an efficient and appropriate solution in the entire field of industrial automation.

Advanced Gripping solutions

7. Axis and robot lifts

Safety separation equipment and racks

Karakuri gravity server units

Servo motors and controllers, PLC modules, I / O expansion modules

CONTACT

My name is Mihai and I am a mechanical engineer, Technical Manager of Robotics Applications within Tech-Con Romania.

We integrate and develop special solutions adapted to the needs of our partners. With my help you can find the products you need and I can give you advice when you are unsure in choosing the right equipment for your application.

Phone: 0730713660

E-mail: mihai@tech-con.ro